LED Light-Curable Adhesives

Dymax offers specially formulated LED light-curable adhesives for use with the BlueWave® LED Prime UVA high-intensity spot-curing system. The adhesives, which range from fast to ultra-fast cure speeds in order to accommodate specific medical device, electronic, and industrial assembly needs, can also be used with the Dymax BlueWave® LED DX-1000 system in spot mode. Dymax BlueWave LED systems offer significant advantages over conventional lamp-curing systems including cooler curing temperatures, lower intensity degradation over time, more consistent cure results, lower energy consumption, and reduced costs.

UV Curing Dome Coatings and Decorative Coatings

Dymax UV curing dome and decorative coatings cure crystal clear in seconds upon exposure to ultraviolet light. The instant, on demand light cure "locks out" airborne contamination. The thicker grades have been optimized for creating a dome which helps clarify and magnify images. The coatings are all one part so no mixing is required and viscosity and flow are consistent, which allows for fewer rejects and less scrap.

Fast cure times of light cure doming resins mean greater productivity and less inventory. Light cure allows for the elimination of ovens, which will save manufacturing space while recovering high energy costs. UV curable dome coatings and decorative coatings are solvent free and do not contain toxic mercury or isocyanates. UV curing dome and decorative coatings are ideal for coating labels, badges, name tags, pens, key chains, decals, and novelties.

Light-Cure Keypad Coatings

Dymax light-curable coatings are designed to be molded onto plastic films and act as an outer layer of interfaces, including keypads. Dymax light-curing keypad coatings offer design flexibility while performing to stringent interface requirements including most common chemical resistance, impact, abrasion, and pencil-hardness specifications. The molding process enables instant fabrication of various contours, shapes, and textures. Set-up costs are minimal compared to similar performing keypads that require injection molds.

Light-Curing Dymax Keypad Coatings vs. Other Keypad Technologies

- Eliminates high costs of injection molding, tooling, and energy use

- Fastest prototyping

- Unlimited range of coloring/design options

- Supports ultra-thin device form factors

- Enhanced tactile response

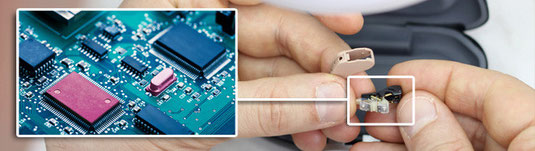

UV/Visible Light LED-Curable Medical Electronics Coatings

Dymax medical electronics coating is a flexible, high-performance, LED-curable coating for electronic applications. This coating contains secondary heat-cure capability for applications where shadowed areas exist. Typical applications include coating of medical micro circuits, sealing, and moisture barrier. Bondable substrates include glass, FR-4, metal, ceramic, and glass-filled epoxy.

UV Curable Optical Assembly Adhesives

Dymax low-stress, low-movement, light-curable optical adhesives cure in seconds to provide the strength and clarity of epoxies. Optically clear, high-tensile-strength bonds of 3,000 psi and shrinkage as low as 0.1% are possible.

- UV/Visible light cure in seconds

- Optically clear adhesive with excellent light transmission properties

- High strength optical adhesive

- Low stress optical adhesive

- Solvent free

- Low shrinkage and low outgassing properties, result in no movement during cure

- One component, no mixing is required

UV curable optical adhesives for optical assembly and lens bonding include grades for VCSEL potting, lens fixturing, lens laminating, lens positioning, and fiber-optic assembly. Dymax optically clear adhesives feature low-shrink, low-stress characteristics, are single component, and exhibit gap filling to 1/4".

OP series UV/Visible light cure optical adhesives are ideal for optical assembly applications such as lens and optical mounting and the attachment of ceramic, glass, quartz, metal, and plastic components.

UV/Visible Light Curing Plastic Bonding Adhesives

UV/Visible Light Curing Plastic Bonding Adhesives. UV light curing plastic adhesives cure in seconds upon exposure to ultraviolet light and/or visible light, even through UV blocked plastics. A solvent-free, worker-friendly plastic adhesive from Dymax, forms high-strengh, environmentally resistant bonds to plastics and other substrates, including polycarbonate, PVC, phenolic, acrylic, metal, glass and ceramic. Because plastic adhesives bond so many different substrates, they are exceptional adhesives for bonding dissimilar materials, something that cannot be done with traditional welding methods and other types of adhesives. Typical UV plastic adhesive applications include display case construction, automotive headlamp assembly, novelty bonding, sign assembly, adhering light fixtures and awards and plastic package assembly

Typical plastic adhesive applications include appliance assembly, automotive sub-assemblies, headlamp assembly, plastic component tacking and sealing, potting, fixturing and ruggedizing plastic housings, high-end displays and jewelry manufacturing, cosmetic household items, and aerospace vibration dampening. These plastic adhesives cure rapidly for high-speed production using either broad spectrum bulb technology or visible light LED technology.